Quintessential to the customer experience, textile packaging is the first tactile touch-point a customer has with their new purchase, making it a highly impactful part of the brand identity.

Having been fortunate enough to have developed premium packaging for some of the biggest brands in the world for the better part of two decades, we not only understand the value of such premium packaging to you and your customer but more so- whether it be jewlery or cosmetic pouches, dust covers, totes or promotional packaging, we know how to produce to your expectations.

More so keeping in mind the role of packaging in the value chain and the quintessential stance brands will have to make towards sustainability and protecting the environment, the DAKS new material lab established in 2015 has been busy developing new packaging solutions for our partners- ranging from JUCO to washable paper and many more options.

Rejection Rate

0.06%

Monthly Production Capacity

3,000,000

Pieces

Improvement in Efficiency

96%

Increase in production in the last decade

Products

Keeping in mind the role of packaging in the value chain and the quintessential stance brands will have to make towards sustainability and protecting the environment, the DAKS new materials lab established in 2015 has been busy developing new packaging solutions for our partners- ranging from JUCO to washable paper and many more options.

Keeping in mind the role of packaging in the value chain and the quintessential stance brands will have to make towards sustainability and protecting the environment, the DAKS new materials lab established in 2015 has been busy developing new packaging solutions for our partners- ranging from JUCO to washable paper and many more options.

Details

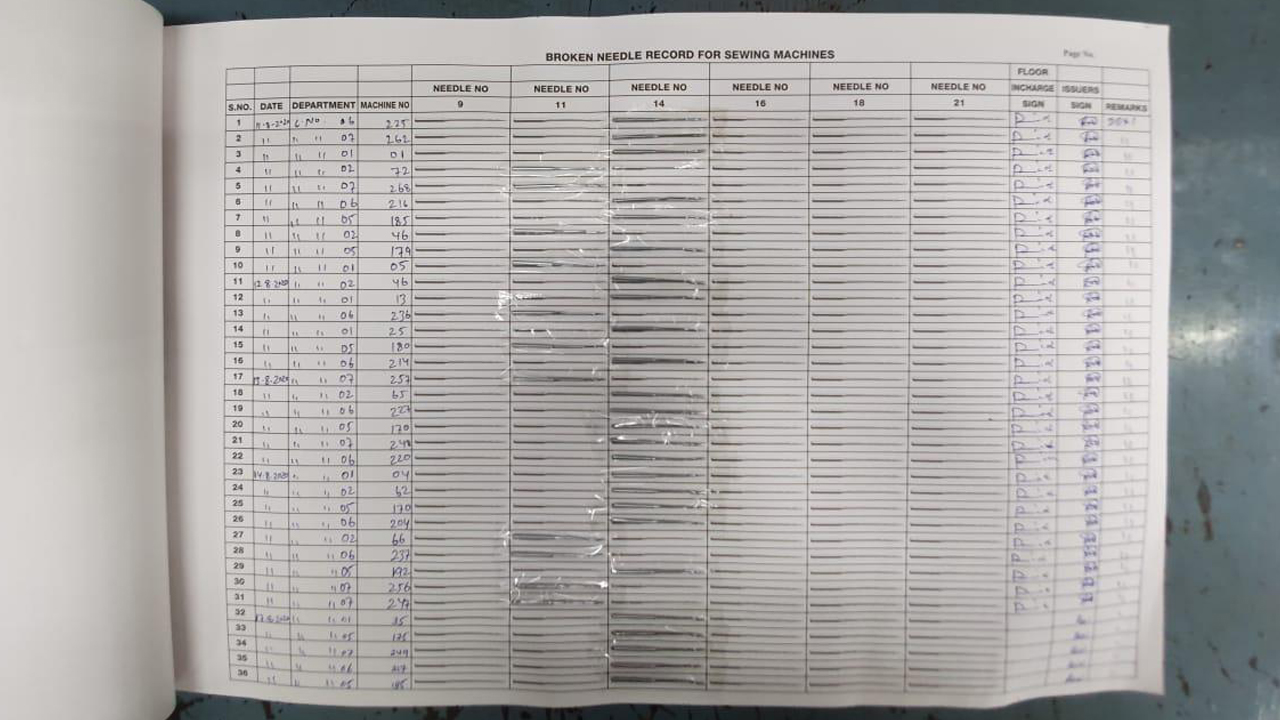

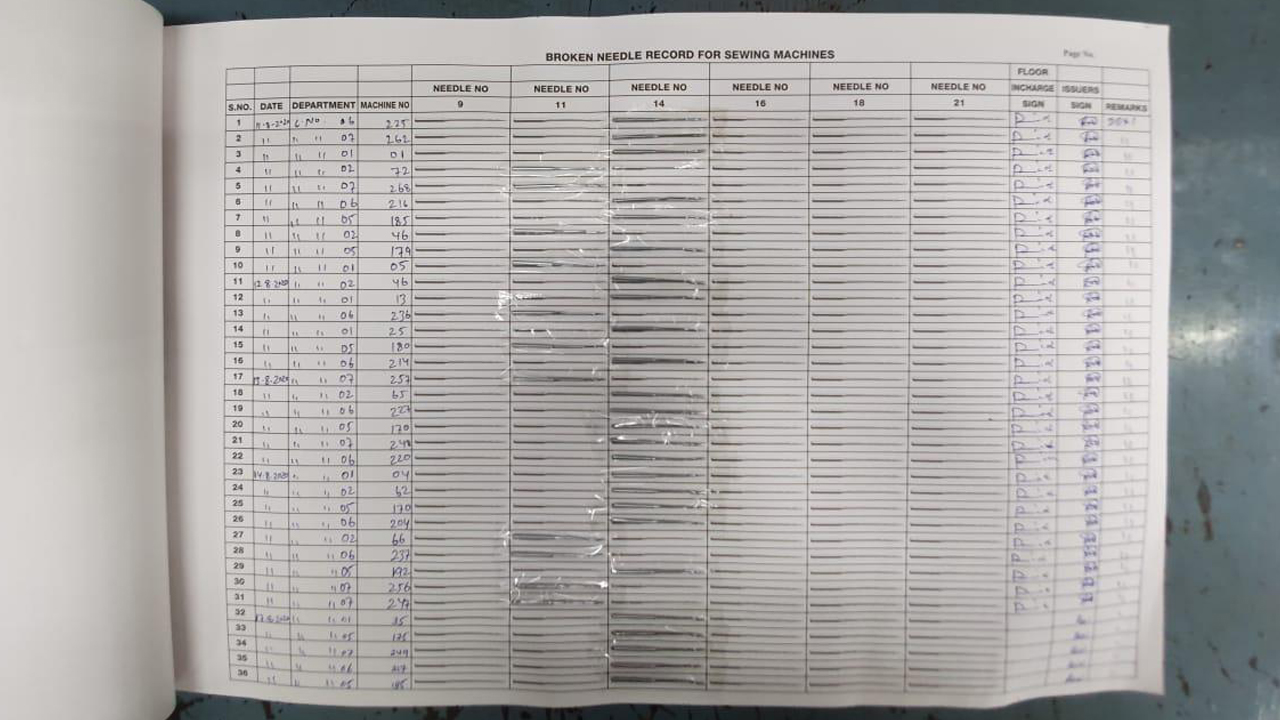

We maintain records of all broken needles and assemble them in a notebook to ensure that no piece of a needle is shipped to customers.

Spot cleaning on products that need it is done in separate rooms other than where we run main production so as to avoid the smell sticking to other products.

Instead of waiting for products to be checked by the QC at the end of the line, we have also set up mobile inspection tables to move through the production lines, maintaining quality in process.

Every product produced is passed through a metal detector machine as a secondary measure to ensure against needles shipping to customers.